Products

LED UV Curing Light for Screen Printing

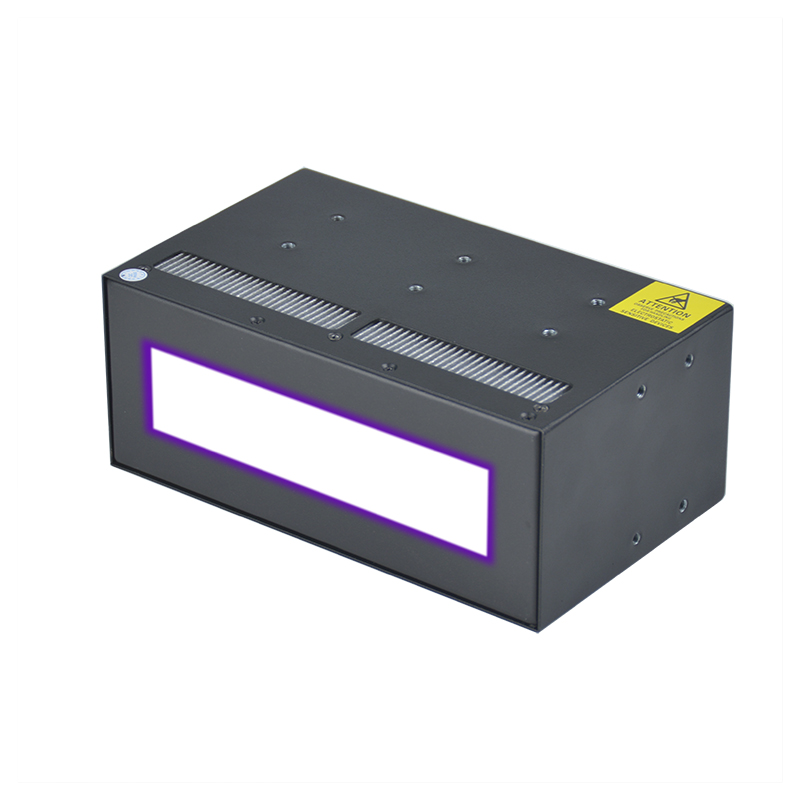

With an irradiation area of 240x60mm and a UV intensity of 12W/cm2 at 395nm, the LED UV curing light UVSN-900C4 is a reliable solution for screen printing. Its high energy and uniform output ensures rapid curing and reduces problems such as blurring and fading during the printing process. This not only improves product quality and efficiency, but also reduces production waste, thereby enhancing the competitiveness of the company and the development of the industry.

Screen printing is the preferred method for producing metal nameplates. However, the traditional curing methods used in this process result in a lot of product problems due to incomplete curing. This article examines the difficulties a screen printer had in producing metal nameplates and how UV LED curing lamps improved the printing process.

The screen printer faces a number of problems when producing metal nameplates. Traditional curing methods require long drying times, resulting in a slow production process. In addition, inconsistent drying can result in poor print quality. These challenges prompted manufacturers to look for alternative solutions to improve the screen printing process. To address these issues, they turned to the UVET's LED UV curing light UVSN-900C4. With an irradiation area of 240x60mm and a UV intensity of 12W/cm2 at 395nm, this curing lamp provides stable and thorough curing of UV inks, ensuring excellent adhesion and longevity of vibrant colors.

The integration of the UVSN-900C4 UV curing lamp has greatly improved the production of metal nameplates. Manufacturers have found that the total curing time has been reduced, allowing them to produce more metal nameplates in the same amount of time. In addition, the lamp's precise control makes the curing process more efficient, eliminating the risk of substrate damage, minimising waste and reducing production costs.

Overall, the UVSN-900C4 curing lamp has had a positive impact on screen printing. The combination of UV LED curing technology and screen printing technology not only improves efficiency, but also improves the quality and consistency of printed materials. As the industry continues to evolve, UV LED systems offer a reliable solution for printing applications, resulting in a more efficient and sustainable production process.

Specifications

| Model No. | UVSS-900C4 | UVSE-900C4 | UVSN-900C4 | UVSZ-900C4 |

| UV Wavelength | 365nm | 385nm | 395nm | 405nm |

| Peak UV Intensity | 8W/cm2 | 12W/cm2 | ||

| Irradiation Area | 240X60mm | |||

| Cooling System | Fan Cooling | |||

Looking for additional technical specifications? Contact with our technical experts.